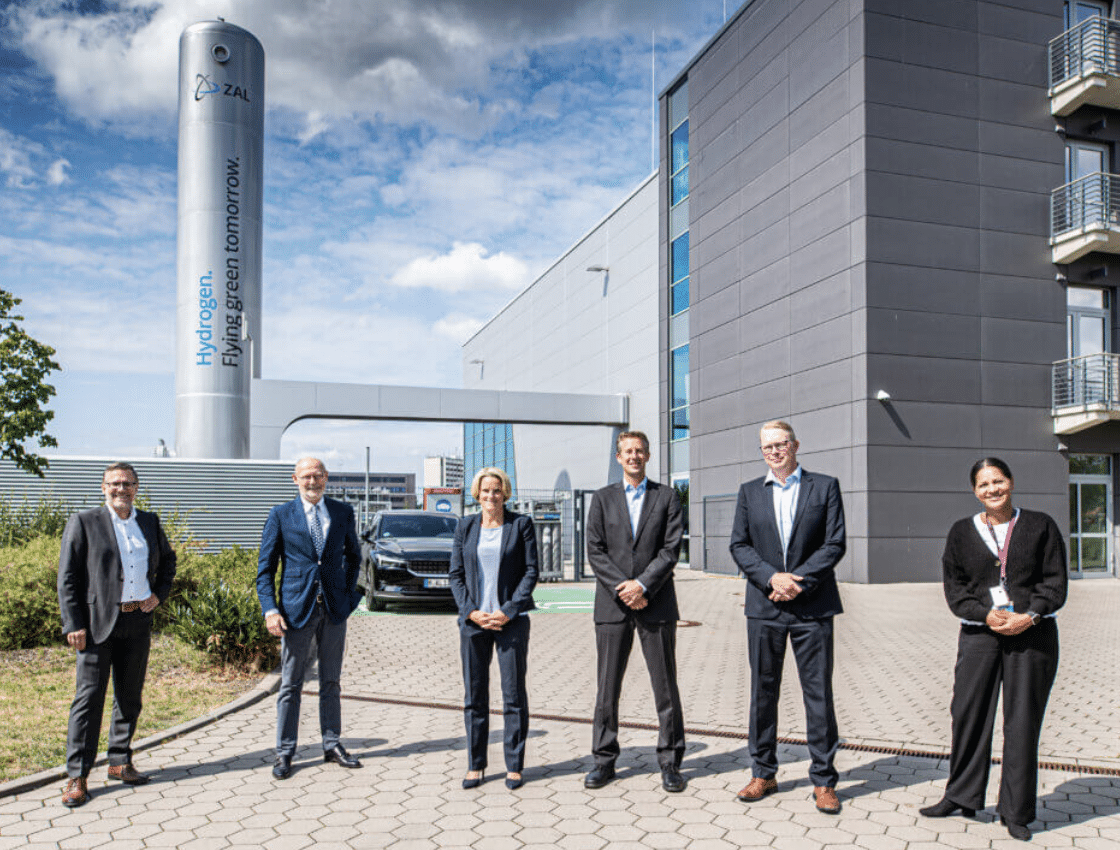

The ZAL Centre of Applied Aeronautical Research has expanded its hydrogen infrastructure with a 20-meter-high, 100 m³ tank. The tank, provided by the company Air Products who will also supply the needed gaseous hydrogen, suddenly increases the capacities available at the research center twenty-fold. Together with Michael Westhagemann, Hamburg’s Senator for Economics and Innovation, the new infrastructure was officially inaugurated earlier in August.

The ZAL Center of Applied Aeronautical Research offers more than 30 partners, including Airbus, DLR, Lufthansa Technik, and ZAL GmbH, extensive facilities for their research into the air transport industry of the future. These groups all agree that hydrogen plays a key role in terms of climate neutrality.

The aviation industry currently faces major challenges: On the one hand, it needs to survive the crisis brought about by the pandemic, while on the other hand – and at the same time – it must strive to make the future of flying emission-free in order to save the planet. The scientific and technical steps needed for this are being developed at the ZAL Center of Applied Aeronautical Research.

ZAL is a member of the Hamburg Aviation cluster and has been active in the field of hydrogen since 2009. ZAL operates the Fuel Cell Lab, rents out fuel cell laboratories, and offers consulting, development, and testing services in the field of fuel cell technology. The Fuel Cell Lab is a cross-sector research laboratory, both for aviation and other mobility applications. A total of approx. 3.7 million euros has been invested in the lab infrastructure since 2015. The 20-meter-high hydrogen tank from the company Air Products, which has now been put into operation, expands the possible test capacities on site by a factor of twenty. The 100 cubic meter storage tank keeps around 400 kilograms of hydrogen on site. The hydrogen is delivered from the Air Products plant in Stade, 30 km away.