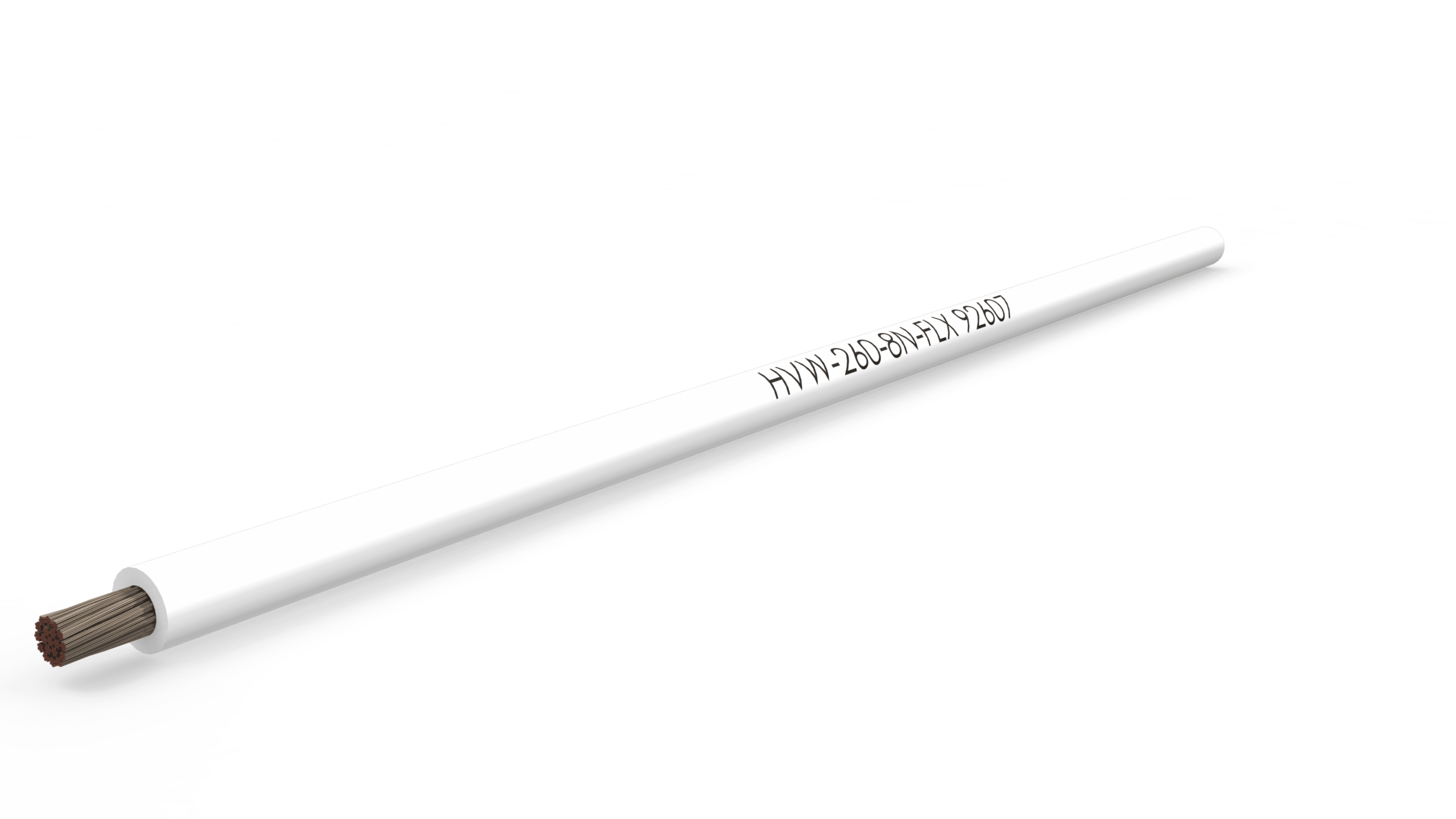

Carlisle Interconnect Technologies (CarlisleIT) released two new high-voltage composite wire families for aerospace applications: a high-voltage composite wire family and an ultra-flexible high-voltage shielded composite wire family. These 1,000-volt composite wire families offer lighter weight and smaller diameters compared to similar extruded constructions in applications up to 260 °C.

Both wire families have exceptional installation characteristics, including Seamless Wrap PTFE jacket technology which offers the advantages of a tape wrap with a smooth outer surface. They also feature a high-strand-count, nickel-plated copper conductors for enhanced flexibility and routing capabilities.

“These new high-voltage composite wire families are joining our existing family of extruded products,” said Tom Turner, product manager for CarlisleIT. “Together, they solve the common problems EWIS engineers encounter in designing power distribution systems. Our high-voltage extruded family solves termination issues with their exceptional stripability, while our two new high-voltage composite wire families address wear issues with their chafing resistance, facilitate installation with their small diameter, and help meet design goals with their light weight.”